- Home Page

- Company Profile

-

Our Products

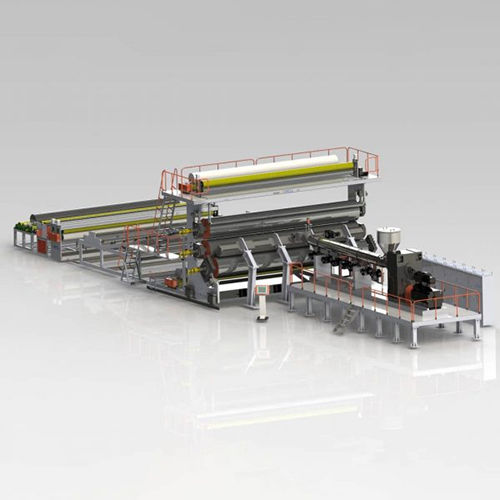

- EVA POE Solar Film Extrusion Line

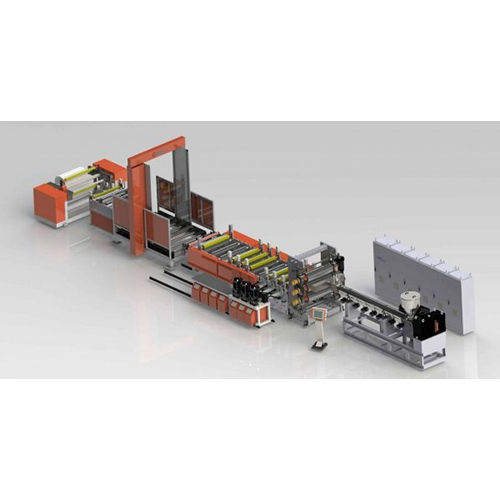

- Solar Extrusion Line

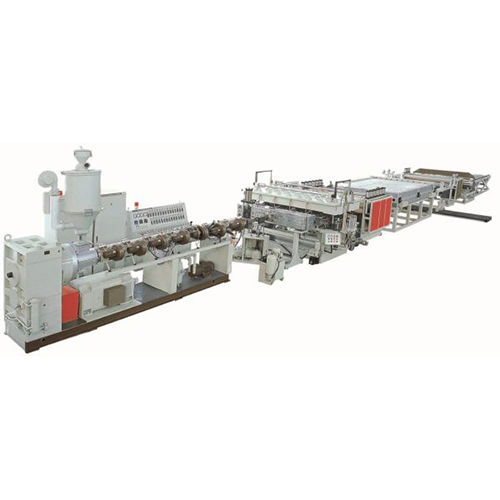

- Sheet Extrusion Line

- PP PS Multiple Layers Extrusion Line

- PET Sheet Production Line

- PET Sheet Extrusion Line

- PP Sheet Extrusion Line

- PP Evoh Multi-layer Barrier Sheet Extrusion Line

- PVC Soft Sheet Extrusion Line

- PET Three Layers GAG Sheet Extrusion Line

- APET PETG CPET Sheet Extrusion Line

- PLA PBS PBAT Starch Straw Sheet Extrusion Line

- PC PMMA Optical Sheet Extrusion Line

- PP PS Sheet Extrusion Line

- PVC Rigid Sheet Extrusion Line

- PC PP PVC Corrugated Sheet Extrusion Line

- Film Extrusion Line

- PVB Interlayer Film Extrusion Line

- TPU Laminating Extrusion Line

- EVOH PP PE High Barrier Multiple Layers Film Extrusion Line

- PVB Film Production Line

- EVOH Multi-layer Film Extrusion Line

- TPU Film Extrusion Line

- PVB SGP Film Extrusion Line

- PETG Film Extrusion Line

- ASA Film Extrusion Line

- CPP CPE Multi-layer Film Extrusion Line

- PVDF Film Extrusion Line

- PVA Film Extrusion Line

- Board Extrusion Line

- Hollow Extrusion Line

- Waterproof Extrusion Line

- Foaming Extrusion Line

- Floor Extrusion line

- Stretch Film Extrusion Line

- Non Woven Extrusion Line

- Contact Us

Showroom

Through EVA POE Solar Film Extrusion Line, accuracy is achieved in the creation of performance films used in manufacturing solar panels. Despite the higher costs, these production lines offer high durability and stability essential for large-scale production lines in companies that offer solar solutions.

Solar Extrusion Lines facilitate the ultramodern fabrication of fundamental solar products, with improved output and utilization of raw materials. These machines can be easily customized and provide dependable outcomes, meaning they are an obvious necessity for companies active in the field of solar energy, focused on achieving productive, durable solutions.

Sheet Extrusion Lines are good opportunities for the production and creation of identical plastic sheets. These tend to be applied to manufacturers in various fields such as packaging, construction, and automotive among others because they enhance productivity by offering assured cost-effective and high-quality production.

Film Extrusion Lines serve as comprehensive solutions for the creation of highly useful plastic films for various sectors. Applicable to packaging, agricultural, and industrial segments they provide high line speed but safeguards product character making it an imperative tool to leverage operational efficiency in a manufacturing context.

Board Extrusion Lines are essential for efficient board production, ensuring uniformity and quality across every batch. Suitable for various board types, they provide precise control over material properties, helping manufacturers produce reliable, high-performance boards that meet market demands.

Hollow Extrusion Lines can address the application needs for making hollow profiles and tubes for the packaging, automotive, and construction sectors. These machines produce accurate and repetitive performance, and they are commonly used for numerous industrial functions where sturdy and reliable plastic parts are desired.

Waterproof Extrusion Lines are designed in a way that ensures it can manufacture extrusion products that can perform well in wet environments. These systems deliver dependable output and have low maintenance needs making them ideal for industries that will need to offer improved water protection without jeopardizing production levels.

Foaming Extrusion Lines provide a suitable solution in the foam production process and offer adaptable products in the market that can be applied in the packing and construction business. They have high efficiency rates, manufacturers should seriously consider purchasing this equipment since the outcome will be quality products.

Floor Extrusion lines enable cost-effective production of endurant floors which include PVC, WPC, and SPC. These machines have the advantage of providing uniformity in quality and surface of produced products, and hence suitable for mass production.

Stretch Film Extrusion Lines give an effective method for developing stretch films to be used in different packaging applications. Thanks to innovative technology and automation, all these lines guarantee effective results with low losses.

Non Woven Extrusion Lines are currently the latest in textile production that has incorporated extrusion technology to excellent fiber formation. These machines increase productivity, reliability, and flexibility and are among the most popular pieces of equipment for manufacturers.

Call Me Free

Call Me Free